VARIABLE INJECTION TIMING VIT

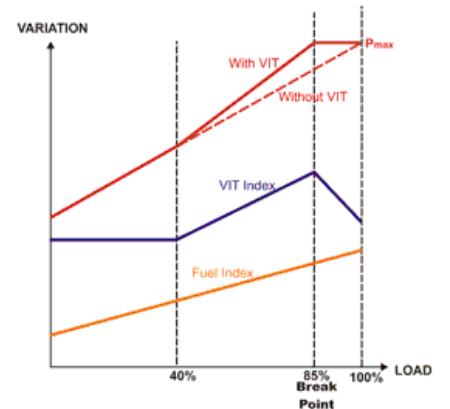

The major issues that must be addressed for the large-scale two-stroke diesel engines are reduction of fuel consumption and NOx emissions. A common technique, which is extensively used in these engines, to achieve greater fuel economy is Variable Injection Timing (VIT). The VIT system is used to modify Start of Injection to control the maximum combustion pressure and achieve optimum performance. Thus, proper operation of VIT system is important for two-stroke diesel engines. Variable Injection timing is also used for small adjustments to consider for the effect of fuel oil quality.

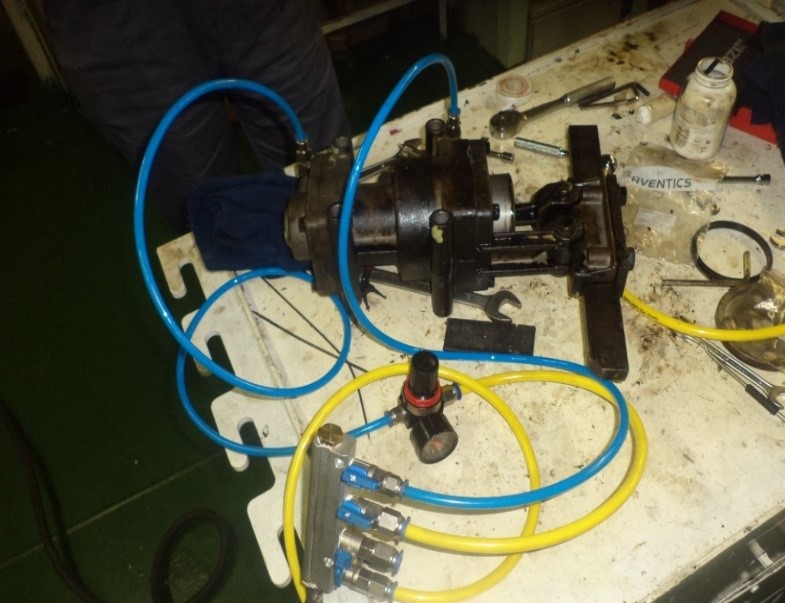

During our attendance for overhauling of pneumatic manoeuvring systems, we have observed that VIT system may neglected, because in any case engine will continue to run with or without VIT. However, considering advantages of well-functioning VIT and harming effect of the defective VIT, it is very important to keep the system in good operational condition.

WHAT IS THE PURPOSE OF THE VIT SYSTEM?

1)

Reduce fuel

consumption.

2)

Ensure safe start to

ahead direction (Functioning only during starting)

3)

Ensure safe start

and give best possible astern performance. (Functioning during starting and

astern running)

4) Ensure safe start during emergency control.

WHAT ARE THE INCONVENIENCIES IF SYSTEM DID NOT PROPERLY ADJUSTED OR SOME OF THE COMPONENTS DEFECTIVE?

1)

You

cannot take advantages of above listed functions.

2) There is risk of EXCESSIVE PRESSURE JUMP (Pcomp-Pmax difference) which may result in piston ring collapse and broken piston rings…Please refer service letter SL1988-241 for more info about pressure jump.

So even if not considering

advantages of the VIT system, should be sure present condition will not cause

any damage on the engine. Therefore, it is very important to keep the system in

well maintained condition.

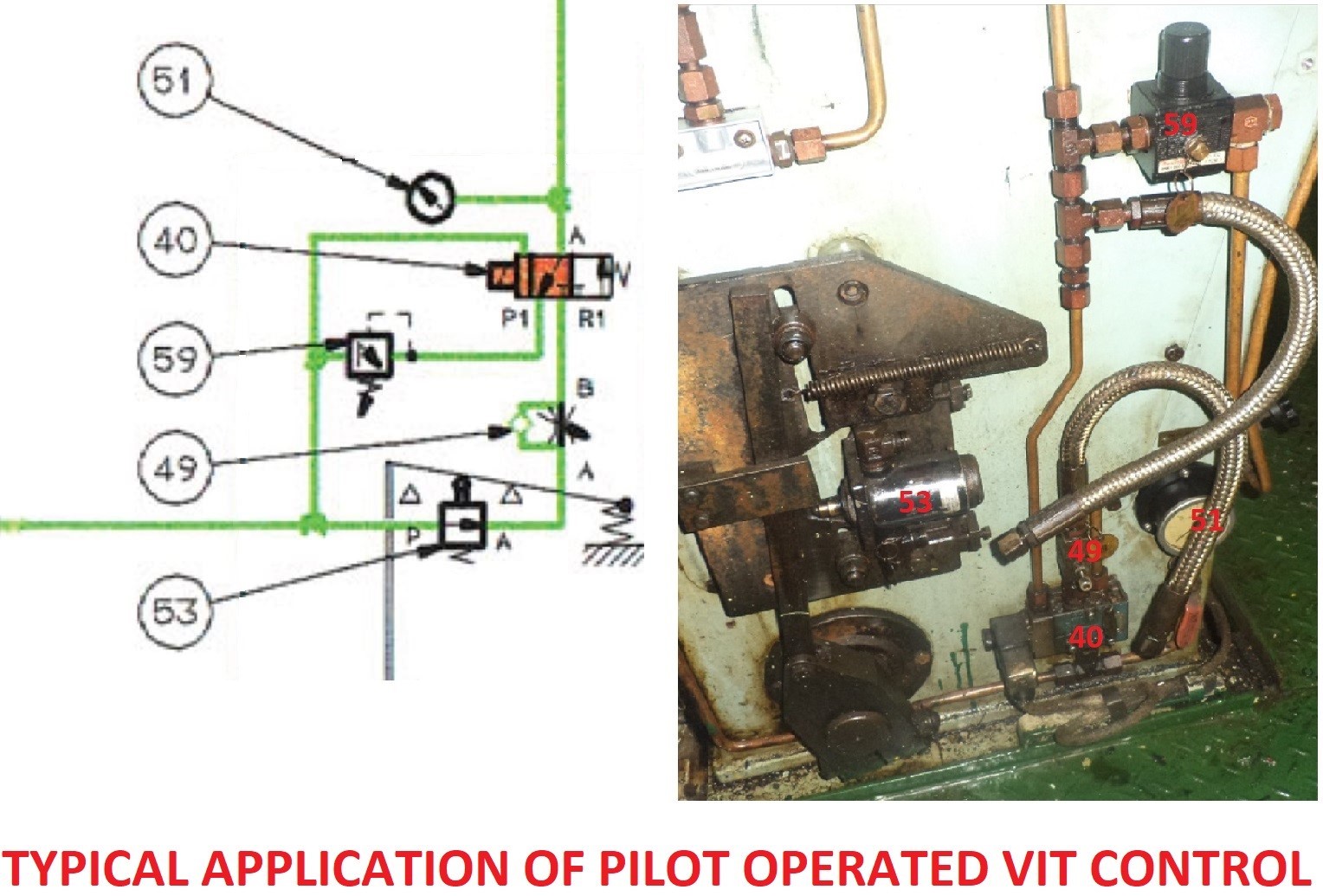

* Some Japanese vessel use different type Pos.40, which is activating by pilot air.

BASIC FUNCTION CHECK OF THE VIT SYSTEM CAN BE SUMMARIZED AS BELOW:

STEP-1 : WHILE ENGINE IS IN ST-BY CONDITION:

1. Check the V/V Pos.40 energized, and you can read pressure on gauge Pos. 51. This pressure value should be same as the break point pressure value.

2.

Read

the VIT indexes, and confirm values are same as break point VIT indexes (See

shop test report).

3.

Check

all VIT actuators activated (Piston out). If some of them shows zero VIT index,

suspect defected VIT actuator or obstructed pump barrel.

4.

Confirm

there is no air leak from any of the VIT actuator.

5.

Increase

and decrease the air pressure by reducing valve Pos.59 and confirm movement of

the VIT actuators. (Such as zero VIT index at 0 bar and full VIT index at 5,0

bar)

6. After testing item-5, air pressure to be adjusted to break point pressure.

STEP-2 : AFTER STARTING

1. Just after starting to AHEAD DIRECTION, confirm V/V Pos.40 deactivated and pressure on the Pos.51 became zero. Confirm VIT indexes became zero as well. If V/V Pos.40 still active after AHEAD RUNNING, risk of the excessive pressure jump. (More than 35-40 bar between Pcomp and Pmax)

2. If engine start and run to ASTERN DIRECTION, Pos.40 should remain energized and break point VIT indexes are maintained.

3. If EMERGENCY RUNNING, you should read less pressure on Pos. 51, which should be equal to VIT index at %40-50 engine load. (See shop test report)

STEP-3 : AFTER STARTING

1. During ahead running, after %40-50 engine load, VIT indexes should gradually start to increase depend on the load.

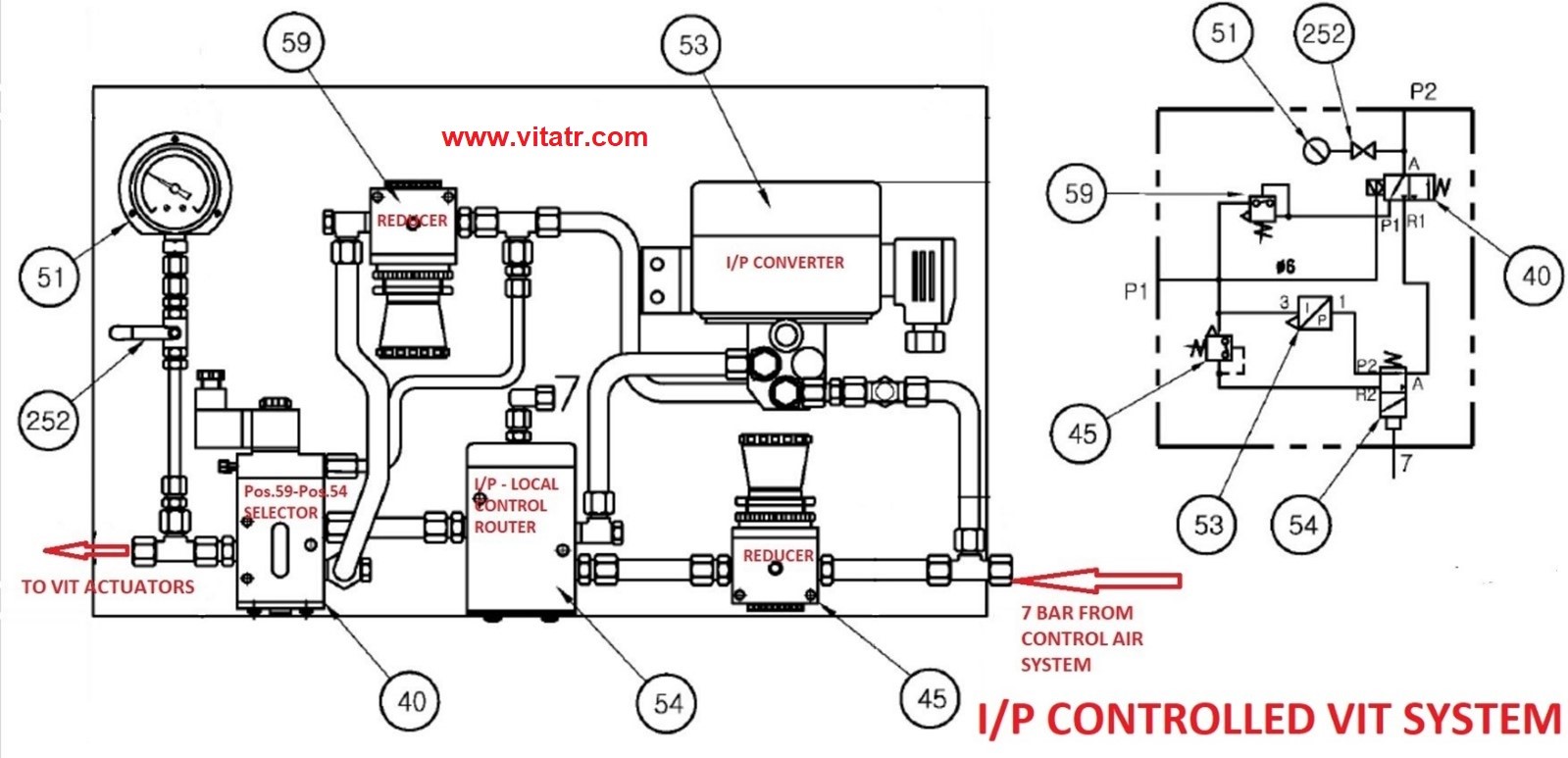

2. VIT indexes should keep steady against 2-3 fuel index variation during rough sea condition etc. If not stable, than need re-adjustment of throttle valve(Pos.49) on pilot controlled system or change the t1-t2 parameters on I/P controlled systems.

If VIT indexes are

increasing depend on the engine load, that means your pilot valve or I/P

converter controlling the system.

It is necessary take engine performance and confirm MCR Pmax obtained at break point and stay same at MCR load… If any abnormalities found need adjust the system.

**Before adjusting individual cylinder Pmax by VIT actuators(+/- 3 bar), please make sure differences on MEP value for individual cylinders not more than 0.5 bar from mean value.

IF YOU HAVE ANY QUESTION, FEEL FREE TO CONTACT

WITH US.

TYPICAL PROBLEMS FOUND IN VIT SYSTEM:

|

|